PCB design | Circuit board design | PCB Design for IoT Plant

Always when starting the journey to the maker world, one of the first things that you have to learn is to understand and design circuits. After all, only then can we bring our ideas to life and interact with the “real world”, right? And, In this context, one of the first things we have contact with is the protoboard, a platform for prototyping very useful and versatile hardware. So in this article I will discuss with details about PCB design or circuit board design, However, the protoboard leaves something to be desired when it comes to the application of circuits in more hostile environments and real applications / outside our laboratories, that is, when things are more serious and more consolidated the prototype is required. Therefore, the next step in a project (after being validated on a protoboard, of course) is to have a PCI - PrintedCircuit Board (or,, PCB: Printed Circuit Board ), so you can go out into the field without fear (and, in addition, give your project a more professional look).

|

| Circuit board design |

And this is

exactly what this series of posts will teach you: how to assemble your own printed

circuit boards, based on our Planta IoT project. That's right: the IoT

Plant project will have its own board and the best: everything is free for you

to edit and make any changes you want! You can also choose to use already

perforated plates, such as perforated phenolite or double-sided perforated

plates , available at the FILIPEFLOP store.

Printed Circuit Boards - what are they?

If you are just

starting out in the maker world, this may be a natural issue at this point in

this post. In a very simplistic way, a printed circuit board or PCB can be

defined as a piece of rigid insulating material (usually phenolite or

fiberglass, generally rectangular in shape) that contains layers of circuits

designed in conductive material (copper), thus forming a “circuit

sandwich”. On the bottom and top surfaces of this board, the electronic

components used in the circuit in question are welded.

As an example,

there are all the “little signs” that we have, including Arduinos. Each

layer of conductive material / circuit is called a Layer, the more complex the

circuit, the more Layers will be needed to make your Printed Circuit Board.

Multi-colored

Printed Circuit Boards

In addition, in

summary, there are other important elements in Printed Circuit Boards:

- Mask

/ Silk : they make it possible to color the Printed Circuit

Boards (in blue, green, black, white, red, etc.) and place inscriptions on

them. This is a very important layer, both aesthetically and in terms

of information about the circuit to be assembled (component codes, values,

polarization, etc.).

- Holes layer :

this is a “layer” used in the development of Printed Circuit Boards that

contains information about each hole to be made in the board, from the

positioning and diameter of each hole to the amount of conductive material

to be placed on the board. around each hole.

Making a simple

analogy:

- Instead of

protoboards, there are copper surfaces (layers, or Layers )

- Instead of

points for connecting the components, you have the holes of a PCB

- Instead of

wires and jumpers, there are the tracks of a printed circuit.

It is also

important to note that not all PCB factories have the same manufacturing

technologies. That is, the more complex (more Layers, shorter trails,

smaller holes, etc.) a board is, the more restricted the range of manufacturer

options is (and the more expensive it is to manufacture, as a result).

What to use to create a PCB design or circuit board design?

Nowadays,

luckily there is several software available for this task, being both paid and

extremely powerful software as well as free and open-source software. PCB design or circuit board design is to cite some examples, we have:

- Eagle

- Altium

- Proteus

PCB Designer

- ZenitPCB

- KiCad EDA

For our series

of posts and development of PlantaIoT Board, the KiCad EDA software was chosen

(called in the articles only KiCad). The main reasons for the choice are:

it is free, open-source, multi-platform software (runs on Linux, Windows and OS

X), user-friendly interface and widely used by the community (there are many

tutorials on the Internet, including in Portuguese , which facilitates

learning). Experienced readers will immediately remember the homesick

Eagle (one of the only free options with possible limitations a few years ago)

when using KiCad.

Note: if you, like me, use Ubuntu (in

my case, version 16.04 LTS), KiCad is already included as one of the packages

in the standard repositories. This means that you can download it directly

from the terminal.

What is possible to do with KiCad?

The answer is

simple: all stages of PCB development. In other words, this tool allows

you to develop your PCB from the design of the schematic circuit to the

generation of Gerber Files (we'll see what that is in detail throughout the

series, don't worry). In summary, there are four steps to follow to

develop a PCB:

- Schematic

circuit drawing.

- Relationship

of the components used with your footprint. That is, correspondence

between each component used and the way it will be drawn on the PCB.

- PCB design

and routing (trail design procedure).

- Generation

of Gerber Files (files used by PCB manufacturers to manufacture them)

It is worth

mentioning that KiCad does not do circuit

simulations. So, before you start designing your project's PCB,

be absolutely sure that it works (do simulations, assemble your

project on the protoboard beforehand and validate it).

Opening KiCad for the first time

After

installing KiCad, when you open it you will see a screen with a blank project

tab. Observe the following figure:

|

| PCB design |

KiCad software opened for the first

time

To start /

create a new project, click File > New Project > New

Project . After naming your project and choosing where it should

be saved, your screen will be as shown in the image below. In blue, the

.sch file stands out, corresponding to the file that will contain the schematic

circuit design of your project.

|

| Circuit board design |

Creating a project in the KiCad

software

IMPORTANT: Save the project to a known

folder / that you have easy access to. If you save anywhere and don't care

about it too much, you will have trouble backing up your project and copying

the Gerber Files.

KiCad usage tips

For a better

use of the tool, I leave the following tips:

- Use it

with two monitors (or a large monitor), as there will be times when it

will be necessary to consult different information on different screens at

the same time.

- Have (a

lot) patience. Designing a PCB from the schematic to having the

gerber files is a lengthy and detailed procedure (especially for those

starting out), where an error can ruin an entire batch of manufactured

PCBs. Therefore, if your project requires a PCB, set aside special

development time for this, preferably in environments where you will not

experience many interruptions.

- Be aware

that (very) hardly a manufacturer will make a part just for you to

test. There is usually a minimum batch that manufacturers impose

(this varies from manufacturer to manufacturer). Therefore, review

the schematic circuit and PCB several times (if possible, ask other people

to review it as well) before ordering fabrication, so the loss of material

(and money) is minimized.

- How to

modify a PCB after its manufacture is not so simple (and extremely not

recommended), if possible, try to leave all possibilities open in the

schematic circuit and in your PCB. For example, if you are going to

use a microcontroller and, from it, use only a few GPIOs / pins, leave the

signals from the other pins available in pin bars (or even islands).

This is interesting because you rarely know all the directions that your project will take and, in case there is a need for expansion of functionalities, it may not be necessary to modify the PCB (= reduction in the final cost of the project). - Avoid

using any software for PCB development in virtual machines. This

software requires some processing and a good amount of RAM, making its use

inappropriate in virtual machines.

- Before

actually developing a PCB, have a list of manufacturers (national and

international) and, at the end of the development, make a budget with most

of them. This list you can go riding with time and need for more

suppliers.

Next step: schematic circuit design

You will be

shown how to draw schematic circuits in KiCad and the schematic circuit design

of the IoT Board Plant. Don't miss the next post!!

PCB Design or circuit board design for IoT Plant

Now, let's go

ahead with the IoT Plant PCB project! Check out the first part of

this series of posts , which show how to make the printed circuit board

for the IoT Plant project shown here on the FILIPEFLOP blog! In

this second post, I will show you how to install a

library of ESP8266 components on the KiCad and how to make the schematic

circuit of the PCB of the IoT Plant. Get to work!

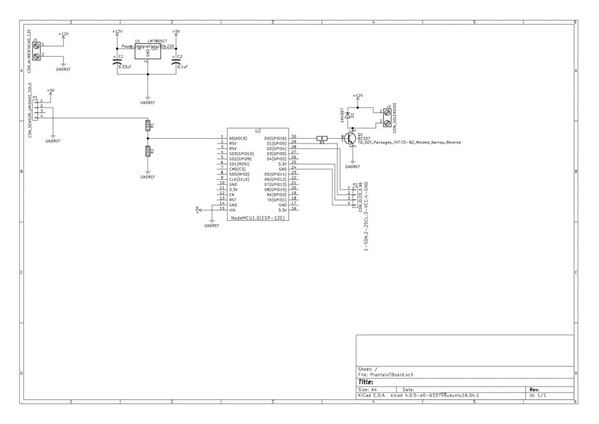

Schematic PCB circuit

Before

starting your schematic circuit design, you must have the schematic of the

circuit in hand (to know what will be drawn). Therefore, below is a figure

with the schematic circuit of the IoT Plant:

|

| Circuit board design |

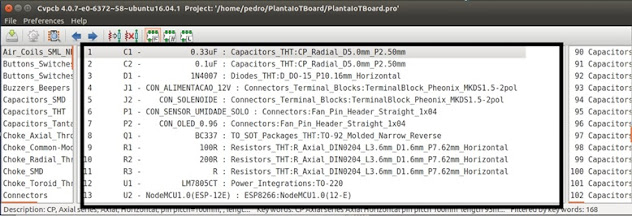

Bill of Materials

In

the circuit design, the components of the list / Bill Of Materials (BOM)

below will be used:

- Two

connectors with 2-terminal screws (on KiCad, they are called

Screw_Terminal_1x02)

- TO-220

encapsulation regulator 7805 (on KiCad, it is called LM7805CT)

- NodeMCU

Wifi ESP8266

- Two

4-terminal female connector bars (on KiCad, they are called CONN_01x04) *

- Resistor

of 100Ohm 1 / 4W . In KiCad, it is simply called a Resistor.

- 200Ohm 1 / 4W resistor . In KiCad, it is simply called a

Resistor.

- Two

electrolytic capacitors (also called polarized capacitors). In KiCad,

they are called Polarized Capacitor.

- Diode

1N4007 **

- BC337

Transistor ***

Legend:

* Although necessary to assemble the circuit and PCB, it is not necessary (it

is recommended, but it is not necessary) to buy this (these) component (s).

Reason: it is possible to weld the wires on the generated islands.

** KiCad does not have this diode by default, but you can use the KiCad

“generic” diode (called Diode only) to design the circuit

*** KiCad does not have this transistor by default. Therefore, you can use

its equivalent, BC817 (both have the same physical dimensions and operating

characteristics, so you can, when assembling the PCB, use BC337 or BC817).

Important:

it is

highly recommended to place a heatsink on the voltage regulator (7805).

Creating the project and opening the

schematic circuit file

First,

you need to create the PlantaIoTBoard project . To

do this, as shown in the topic “Opening KiCad for the first time”, create the

project. After that, double click / open the project's .sch file . You

should then see the schematic circuit file with nothing drawn, as shown in the

following figure:

|

| Circuit board design |

Screen that will contain the schematic

circuit design of PlantaIoT Board

Now,

everything is ready for the schematic circuit design!

ESP8266 libraries - installation

Before

proceeding with the circuit design, it is necessary to install a component

library from the ESP8266 line. This is necessary because, unfortunately,

these components do not come by default with KiCad, but the good news is that

it is quite easy to get and install them (I found a good library for

ESP8266 in

this GitHub repository ). To install the library, follow the

procedure below.

Note: the procedures

described focus on Linux, but it is easily done on Windows with similar

actions.

- First,

make a clone of the repository on your computer (in a known / easily

accessible location)

In Linux, through the terminal, execute the following commands:

?

|

1 two 3 4 |

cd ~ mkdir -p ~/kicad/libraries/ cd ~/kicad/libraries/ git clone https://github.com/jdunmire/kicad-ESP8266 |

- On the

schematic circuit screen, go to the Preferences > Component

Libraries > Add menu and add the

ESP8266.lib file (which you downloaded when you cloned the repository).

- To add the

footprints of the components: on the main KiCad screen, open the file with

the name ending in “_pcb”, access the Preferences menu > Footprint

Libraries Wizard and add the file ESP8266.pretty (contained

where you cloned the repository).

That

done, KiCad will be ready for you to be able to design schematic and PCI

circuits for the project.

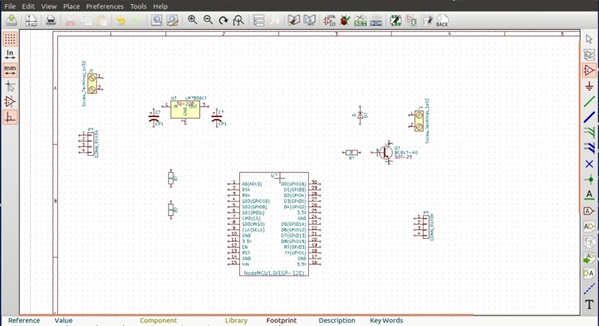

Placing the circuit components in the

schematic

To

place a component in the schematic circuit, follow the procedure below:

- Go

to Place > Component

- Click on

the "sheet" location of the schematic circuit where you want to

add a component

- The

following window will appear:

|

| Circuit board design |

- Navigate

through it (or type the name of the desired component in Filter:, select

the desired component and click OK.

- Once this

is done, the window will close and it will be possible to position the

component on the “sheet”. To confirm the location of the component,

click on it with the left mouse button.

- If you

want to rotate the component, press the Esc key, right-click on it and

click Orient Component. Rotate it as desired.

Do

this procedure for all components of the circuit (according to the list of

components shown in this post). Your schematic circuit should look similar

to the figure below:

|

| Circuit board design |

Naming the components

You

may have noticed that the components are unnamed "formal" (resistors

called "R?", Capacitors called "C?", Etc.). KiCad has

a feature to automatically name the components of a schematic

circuit. Such functionality is called Annotate schematic

components . to access it, just go to Tools > Annotate

Schematic .

Going

to this option, a window will appear. Click on Annotate and

all components are automatically named. Observe the following figure:

|

| PCB design |

Connecting the components

To

connect the components, we will use wires . To place a

wire between a terminal of one component and another element (terminal of

another component, for example). follow the procedure below.

Tip: For this task, the use of zoom is recommended. To

zoom in, roll the mouse scroll up and, to zoom out, roll the mouse scroll down.

- Go

to Place > Wire

- Click on

the terminal of a component you want to join to another element

- Move the

mouse to the target element to be joined by the wire (terminal of another

component, for example). Click on it once.

Do

this procedure until the circuit has the connections identical to the complete

schematic of the PlantaIoT Board provided here (at the beginning of this post).

Using Power Ports for PCB design or circuit

board design

Power Ports are elements that

represent power (+ 12V, + 5V, GND, etc.), as shown in the image below:

|

| PCB design |

These

elements are very useful as they make the schematic circuit cleaner and more

understandable (especially for large circuits). To add them, follow the

procedure below:

Go

to Place > Power Port

Click

on the "sheet" location of the schematic circuit where you want to

add a Power port

The

following window will appear:

|

| PCB design for IoT |

- Navigate

through the “power” options and place the + 12V, + 5V and GNDREF power

ports according to the complete schematic circuit provided in the

article. At the end of this process, your schematic circuit should

look similar to the figure below:

|

| PCB design MAD PCB |

Schematic ready!

At

this point, your schematic circuit of the IoT Board Plant is ready!

Next

steps: generate the PCB and gerber files (both will be seen in

part 3 of this series).

PCB Design for IoT Plant PCB Designor circuit board

design

Concluding

the series of posts on the IoT Board Plant, let's see how a PCB is made and

what is needed to send it for manufacturing. Check out the first and second parts of this

series, which show the fundamentals and tools for PCB projects!

In

summary, in this third and last post of the series, I will show how electronic

components are associated with their real representations on the board

(so-called footprints), how to make the PCB and, finally, what needs to be done

to send the PCB to manufacture in a specialized company. Get to work!

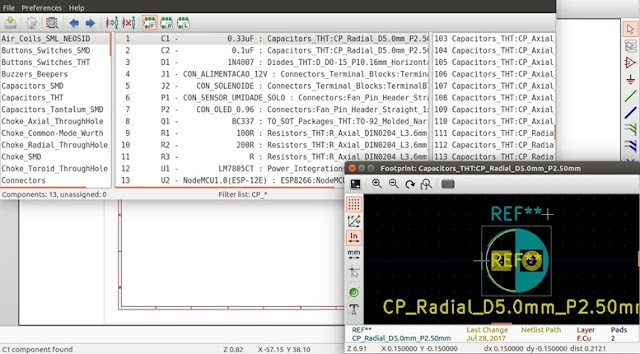

Relating components and their actual

representations

Before

we go into the actual design of the PCB, an important task needs to be done:

the relationship between the components of the schematic circuit and their

actual representations (in more technical vocabulary, called

footprints). In other words, it is necessary to inform KiCAD how we want

the electronic components to be represented on the PCB.

To

access this tool, we will use the shortcut on the toolbar, as shown below:

|

| PCB Design |

Clicking

on it, a new window will appear (depending on your computer this may take a few

seconds, as this is one of the heaviest parts of KiCAD). This is the footprint

association window. It is divided into three parts, with the following

purposes:

- Central

part: a list of all the electronic components of your schematic circuit

- Left part:

component categories / types

- Right

part: all components of the selected category / type

Now

is the time to, in addition to navigating the components, view their footprints

in real time, to be more sure in the choice. For this, a footprint

visualization tool will be used, accessible by a shortcut in the footprint

association window itself, as shown in the following figure:

|

| PCB Design |

Here

comes the greatest need to have a large monitor or, preferably, two monitors

for this type of development. Reason? It will be necessary to

navigate through the footprint association window, always keeping an eye on the

corresponding footprint that appears in the footprint visualization

tool. It is not impossible to do this with just one monitor, although it

is a little “messy”. Using only one monitor, an image with a suggested

window layout follows:

|

| PCB Design |

With these two tools open, select component by component in the central part of the footprint association window and choose the most suitable ones for the board. My suggestion is to use the selections seen in the central part of the footprint association window, as highlighted in black in the figure below.

|

| PCB Design |

Note: it is not necessary

to strictly follow this suggestion, you are free to choose the types of

components you want, but keep in mind that the suggested selection aims at

greater availability of the components on the market and ease of assembly /

welding of the plate.

Once

the association is made, just close the footprint visualization tool, close the

footprint association window.

Netlist

The

last step before we start, in fact, for the design and routing of the PCB is

the generation of the Netlist. In summary, Netlist is a file that

describes all the connections that should exist between the electronic

components of your project, in addition to the relationship between the

components and your chosen footprints. This is something very important,

being the link between the PCB project and the schematic circuit.

To

generate it, follow the procedure below:

- On the

schematic circuit screen, on the toolbar, click on the button with a

drawing with the inscription “Net”, as shown in the following figure:

Circuit board design - A window

will appear. In it, select the option "Default Format" and

click "Generate". This process is also usually quite

cumbersome for KiCAD, so it can take a few seconds depending on the

complexity of your schematic circuit and your computer's settings

Circuit board design - Note,

highlighted in the previous figure, the name of the generated Netlist file

(PlantaIoTBoard.net). It can be seen from your project files on the

main KiCAD screen, as shown in the figure below:

Circuit board design

PCB: component layout

The

time has come to design, in fact, the PCB! For that, we will need to run

the Pcbnew tool . To do this, use the shortcut on

the toolbar on the printed circuit screen, as shown in the following figure:

| PCB |

Pcbnew

will open. The first thing to be done on it is to load the Netlist

generated in the previous topic. To do this, click on the shortcut for

“Read netlist” shown in the figure below.

|

| Circuit board design process |

On

the screen that appears, click "Browse", select your Netlist file and

click "Read Current Netlist" and then "Close". Reading

the file, as well as other things described here, may take a few seconds

depending on the configuration of your computer and the complexity of your

circuit.

After

reading, the Pcbnew screen will be a little different, containing all the

components of the la circuit, as well as the connections between them. See

the figure below:

|

| Circuit board design |

You

may have noticed that the components are all “stacked up”. To resolve this

situation and space out the components, there is a feature of KiCAD called

“Global Spread and Place”. To use it, follow the procedure:

- Go to

“View> Switch Canvas to Default”

- Use the

shortcut illustrated in the following figure to enter to enable the “Mode

Footprint”.

- Right-click

on any empty (free of components) on the screen and access the option

“Global Spread and Place”. There, click on “Spread out All

Footprints”. If a dialog box appears, answer ok / yes and you are

done! Your circuit should look similar to the figure below:

Circuit board design - Click on

the shortcut in step 1 again to exit “Mode Footprint”

Note: although this is a

very useful feature to make the circuit more visible, it will not consider the

connection between them in the layout! Therefore, we still have to

reposition them according to our needs and / or connections between components.

Here

comes the “artistic side” of the thing: position the components so that they

can be organized in a way that is easy to assemble (maybe even do with single

layer, if you're lucky!). This is something that does not have much to

explain, except to say that it must be done with common sense and always aiming

at the best possible assembly (by "best assembly", understand the

simplest, after all who will assemble / weld the sign when ready is you).

This

is also the longest step: depending on your experience and “spatial view” of

the circuit, it can take hours (maybe days), but don't be discouraged: it is a

valuable experience for the future.

In my case, I found that the most suitable layout (aiming for a single layer

board and simple to assemble) is the one shown below:

|

PCB: board routing

It

is time for card routing. The routing consists of connecting the

components with the tracks of the printed circuit, in the desired

configurations (thickness, diameter of the hole and its metallization, distance

between tracks and the rest of the circuit, etc.). For beginners, printed

circuit tracks are analogous to wires connecting component terminals.

There

are two routing options: automatic and manual. The automatic is not

recommended (especially for those who are starting in this area) because, in

addition to doing a job that will need to be understood by you, it leaves a lot

to be desired regarding the use of the layer (in short, it is “waste” in making

trails and use layers, which means more expensive PCBs to manufacture and

inefficient in space utilization). For these reasons, we will do manual

routing in this article.

To

do this, do the following:

- Select the

bottom layer, as shown in the figure below.

Note: The name B. Cu means:

B: Background Layer

Cu: Layer with Copper / conductive surface. - That done,

it means that every routing we do will be applied to the selected Layer

(in this case, lower). To make a track, in the right sidebar of

Pcbnew, click on “Add tracks and routes”, as shown in the figure below:

- Choose a

Pad ("circle" around the component terminal) and click once with

the left button. Drag the mouse to the target pad and double-click

with the left button. There, you made your first track! It will

be as shown in the figure below:

Circuit board design - Now repeat

the procedure for all the tracks to be done. Here, again, it is

something that requires a more “artistic” side, because you should try, at

all costs, to put all the tracks on this layer. Remembering that a

track can NEVER pass over another one on the same Layer!

This is something that can take a lot of time (and patience), but you must go through this experience (it is valuable for future projects). Below is the routing that I found most convenient (and that can be done in a single layer):

|

| Circuit board design |

PCB: defining the plate area and ground

plane

Now,

it will be necessary to define the area of the plate, that is, of the entire

area available for the project, select which is really relevant / should

constitute your plate. In addition, the ground plan will be defined, which

consists of filling all unused space by the trails with a ground conducting

plan. The purpose of the ground plane is to serve as a protection against

electromagnetic noises that fall / are irradiated on the plate. These

noises, if impacted on the plate, will be more likely to be directed to the

ground planes than to the circuit tracks, not harming the signal that travels

through them. If the ground plan is not made, the noises will directly impact

the trails, impairing (and, often, making unfeasible) the correct functioning

of the circuit.

To

define the area of your plate and the land plane, do the following:

- In the

toolbar on the right, select the option “Add filed zones”, as shown in the

figure

Circuit board design - Left-click

where you want to be one of the vertices of the plate. A window will

appear, asking for details of the plan that will be created. There,

select the GNDREF option and click OK. See the figure below:

Circuit board design - Now,

clicking with the left button to define the vertices of the plate, go

through the entire plate, forming a rectangle. At the last vertex,

double-click the area to be closed.

Tip: do not make the rectangle too close to the components, this can increase the chances of PCB manufacturing errors. - Click on

“Perform PCB Rules Check”, as shown below

Circuit board design - A window

will appear. Click on “Start DRC” and then on Ok.

Important: this step will check your PCB for errors. If any arise, correct them immediately. - Once this

is done, your plate will be routed, with a defined area and with a ground

plane, as shown in the figure below:

Circuit board design

3D preview of your board

For

your delight, you can have a 3D preview of your board in KiCAD! To do this,

on Pcbnew, go to “View> 3D Viewer”. Notice how the board looks in 3D:

|

| Circuit board design |

And to have the plate manufactured, how do

I do it?

The

PCB project has come to an end, but what about making the board? How is

done?

For

this, one of the most popular ways is to use Gerber Files. The Gerber

Files are files generated by your PCB design program that show the manufacturer

how each detail of the board should be done, so in possession of these files

the manufacturer can manufacture the boards exactly as specified.

To

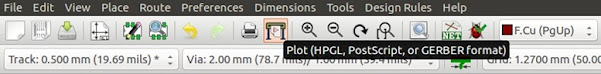

generate your card's Gerber Files, follow the procedure:

- On Pcbnew,

click on Plot, as shown below

Circuit board design - On the

screen that appears, leave it as shown in the figure below

PCB Design - Click on

“Browse” and define a directory where the generated files will be

saved. If you prefer, create a sub-directory within your project's

directory, for greater organization.

- Click on

“Plot”

- Then,

click on “Generate Drill File”, leave it as shown in the figure below,

place the same output directory as in step 4 and click on “Drill File”.

Okay, everything you need to have your PCB manufactured is in the directory you chose!

|

| Circuit board design |

Now

all you have to do is send the Gerber Files and Drill Files to the manufacturer

and request a quote (and manufacturing, if the budget pleases you, of course).

No comments

Note: Only a member of this blog may post a comment.